|

|

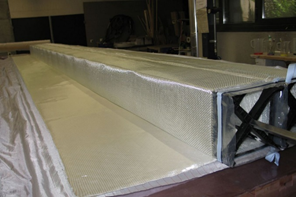

| The processing of carbon, Kevlar or glass fibres is one of our core tasks in the production of light mobile solutions. We mainly process dry fabrics, which are impregnated with epoxy resin under vacuum after being placed in a mould. This wetting process is called vacuum infusion. The parts are then completely cured in an oven and slowly cooled down. The parts are cut by hand or by CNC machine. Finally, the parts can be polished or painted. Thanks to this stress-free curing we can produce parts with low distortion and therefore very precise. |  |

|

Tolerances in a few hundredths of a millimetre per metre can be produced with repeat accuracy. Light, complex components are perfectly suited for additive manufacturing - this is why our company has been dealing with this topic for several years. components, regardless of their geometry. Prototypes, unique pieces, small and large series. Additive manufacturing shapes the future of the manufacturing industry like no other process. By means of additive manufacturing or laser-sintering or laser melting, components with the highest material requirements can be manufactured, coated or repaired. In comparison to traditional, ablative manufacturing processes such as turning or milling, the design determines the manufacturing process in additive manufacturing, which is why it is also called "Design for Additive Manufacturing" (DfAM). |

|